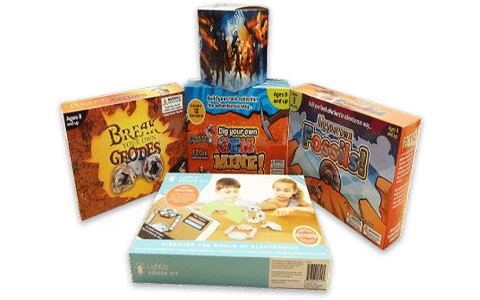

In today’s competitive toy market, custom packaging does more than protect your product—it tells your brand’s story and delights customers from the moment they lay eyes on the box. From material selection to finishing techniques, the decisions you make directly impact functionality, aesthetics, sustainability, and cost. Read on to learn how to balance these factors and create a memorable unboxing experience through smart packaging design.

1. Define Your Functional Requirements

Before selecting materials or deciding on print processes, clarify what your packaging must achieve:

- Protection & Durability

Toys can be fragile or oddly shaped. Choose substrates with sufficient rigidity (e.g., high‐quality paperboard or greyboard) to prevent crushing or deformation during transit. - Safety & Compliance

Ensure inks, coatings, and adhesives are non-toxic and meet child‐safety standards (e.g., CPSIA in the U.S.). - Shelf Appeal

Vibrant graphics, clear windows, and tactile finishes enhance shelf presence and boost impulse purchases.

2. Material Options for Toy Packaging

a. Paperboard Grades

| Grade | Finish | Ideal For |

|---|---|---|

| Solid Bleached Sulfate (SBS) | Coated white | High-end prints, vibrant colors, luxury toys |

| Clay Coated News Back (CCNB) | White face, grey back | Budget-friendly, bright printing on the front |

| Kraft Board | Natural brown | Eco-focused brands, rustic or minimalist look |

| Greyboard | Uncoated grey | Rigid structures, inserts, heavy toys |

- GSM (grams per square meter): Thicker boards (300–450 gsm) offer sturdiness; thinner boards (200–270 gsm) work for lightweight toys or inner sleeves.

b. Sustainable Alternatives

- Recycled paperboard

- FSC®‑certified substrates

- Sugarcane bagasse board

Promoting eco-friendly custom packaging can become a unique selling point for your toy line.

3. Printing and Finishing Techniques

A well‐executed finish elevates both look and feel.

- Printing Methods

- Offset lithography for high-volume, detailed graphics.

- Digital printing for short runs, quick turnarounds, and variable data (e.g., personalized editions).

- Coatings & Laminations

- Matte or gloss lamination to protect the ink and enhance tactile appeal.

- Aqueous coating for a cost-effective, eco-friendly sheen.

- Special Effects

- Spot UV or Spot gloss to highlight logos or key graphics.

- Embossing/Debossing for a premium tactile impression.

- Foil stamping in metallic or matte finishes for luxury accent.

Use these options strategically in your packaging design to draw attention to brand elements without driving costs unnecessarily high.

4. Structural Design Considerations

- Die-cut Windows

Let children and parents see and touch the toy before purchase. - Auto‑lock or Crash‑lock Bottoms

Speeds up assembly in your factory or warehouse. - Dividers and Inserts

Keep multi-piece sets organized and secure. Choose matching board or recyclable molded pulp.

Work closely with your packaging supplier to prototype dielines and mock-ups, ensuring the structural integrity aligns with both your product dimensions and retail requirements.

5. Cost Management Strategies

- Balance Run Length & Method

Longer print runs reduce per-unit costs for offset but commit you to inventory. Digital is more flexible for limited-edition toys. - Optimize Color Plates

Use spot colors for simple graphics to avoid the expense of full CMYK. - Standardize Box Sizes

Limiting custom dielines to a few sizes can unlock volume discounts on board and reduce die costs.

6. Integrating Branding and User Experience

Successful packaging design tells a cohesive story:

- Color Palette & Typography

Reflect your toy’s personality—bright primaries for educational toys, pastels for collectible figurines. - Interactive Elements

Pull tabs, pop-ups, or peel-off panels can add delight and encourage social sharing. - Brand Messaging

Keep copy concise, child-friendly, and focused on play value or learning outcomes.

Choosing the right combination of board grade, print process, finishing techniques, and structural design is essential for crafting effective custom packaging that protects, engages, and sells your toys. By prioritizing your brand identity, budget, and sustainability goals, you can create packaging that not only houses your product safely but also elevates the unboxing experience.